Bydgoszcz Case Study - GCEM 40E

The background:

The Bydgoszcz Combined Heat and Power Plant (CHP) has a rich history dating back to 1929, with the initial operation of a municipal power plant in Jachcice. Over the decades, the plant expanded, and by 1971, it had formed the Bydgoszcz CHP Group, incorporating the newly established Bydgoszcz II Power Plant. Today, it operates under the PGE Polish Energy Group S.A., Poland’s largest power and heat supplier.

The Bydgoszcz Combined Heat and Power Plant (CHP) has a rich history dating back to 1929, with the initial operation of a municipal power plant in Jachcice. Over the decades, the plant expanded, and by 1971, it had formed the Bydgoszcz CHP Group, incorporating the newly established Bydgoszcz II Power Plant. Today, it operates under the PGE Polish Energy Group S.A., Poland’s largest power and heat supplier.

The group comprises three production units:

- Bydgoszcz I CHP Plant, which supplies heat to the western and central parts of Bydgoszcz.

- Bydgoszcz II CHP Plant, the primary supplier of heat and power to the city, producing electricity in high-efficiency cogeneration.

- Bydgoszcz III CHP Plant, which operates under Bydgoszcz II.

The Problem:

The need for modernization became apparent with the tightening of emission standards under the Industrial Emission Directive (IED). The steam boilers K3 and K4 at Bydgoszcz II required updates to reduce sulphur dioxide (SO₂) levels to below 200 mg/Nm³ and particulate matter to below 20 mg/Nm³ to remain operational beyond 2015. Without this, the plant risked non-compliance, potential fines, and a halt in operations vital to Bydgoszcz’s households and industry.

The Solution:

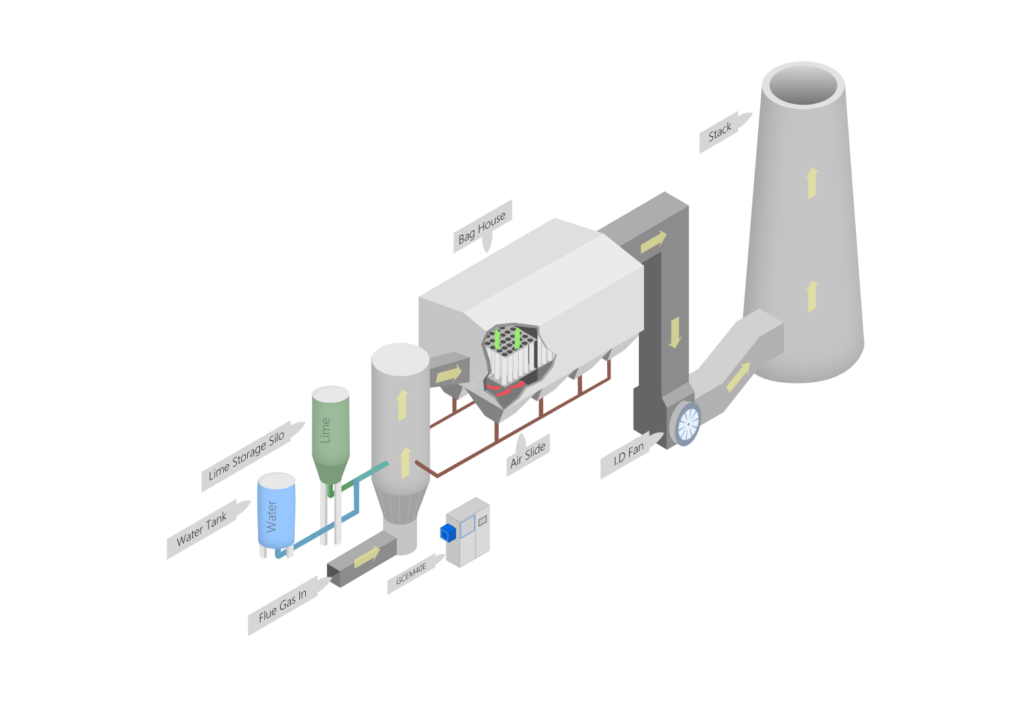

In 2013, PGE partnered with Alstom Power Sp. z.o.o. to construct a cutting-edge Flue Gas Desulphurisation (FGD) plant using Alstom’s proven semi-dry NID™ (Novel Integrated Desulfurization) technology. The installation effectively removes acidic pollutants from flue gas by injecting hydrated lime, converting harmful gases like SO₂ and HCl into inert compounds. Key components include a compact reactor, integrated mixer and hydrator, and advanced bag filters.

Pentol, with over 20 years of experience in Continuous Emission Monitoring Systems (CEMS), was selected as the supplier for process monitoring and control, utilizing CODEL instruments. Their systems provide continuous and accurate measurements, enabling compliance and optimized operations.

Technical Details:

Three CODEL GCEM 40E hot extractive multigas analysers and one VCEM 5100 flow analyser were installed as part of the FGD system. These tools continuously measure SO₂, HCl, CO₂, H₂O, and other gases to optimize the FGD process, reduce reagent consumption, and maintain operational efficiency. The VCEM 5000 ensures precise gas flow measurements at the FGD inlet, critical for proper mixing and avoiding lime fallout.

Results and Future Plans:

By August 2015, the FGD system was fully operational, achieving SO₂ levels below the mandated 200 mg/Nm³ and ensuring compliance with IED standards. This marked a significant step forward in modernizing the plant.

Building on this success, PGE has initiated the construction of a DeNOx plant to further reduce nitrogen oxide (NOₓ) emissions, with completion planned before the end of 2017. This project highlights the plant’s commitment to environmental sustainability and regulatory compliance.

The modernization of the Bydgoszcz Combined Heat and Power Plant showcases how advanced FGD and monitoring technologies can align industrial operations with stringent environmental regulations. CODEL’s reliable monitoring solutions played a pivotal role in optimizing the plant’s emissions control, ensuring sustainable operations, and securing a cleaner future for the region.

GCEM40E CEMS Extractive Gas Monitor

The GCEM40E hot extractive multi-channel gas analyser is CODEL’s industry-proven continuous emissions monitor for difficult applications. Designed exclusively for use on a wide range of applications where the flue gas temperature is abnormally high, low or saturated.

Features & Benefits

- Single or Multi-species infrared absorption analyser

- Hot Extractive System

- CO, NO, NO2, NOx, SO2, CH4, HCI, CO2 & H2O

- Gas temperature and pressure sensors

- Analogue & serial digital output.