The Use of Continuous Emission Monitors in Cement Plants

The Use of Continuous Emission Monitors (CEMS) in Cement Plants

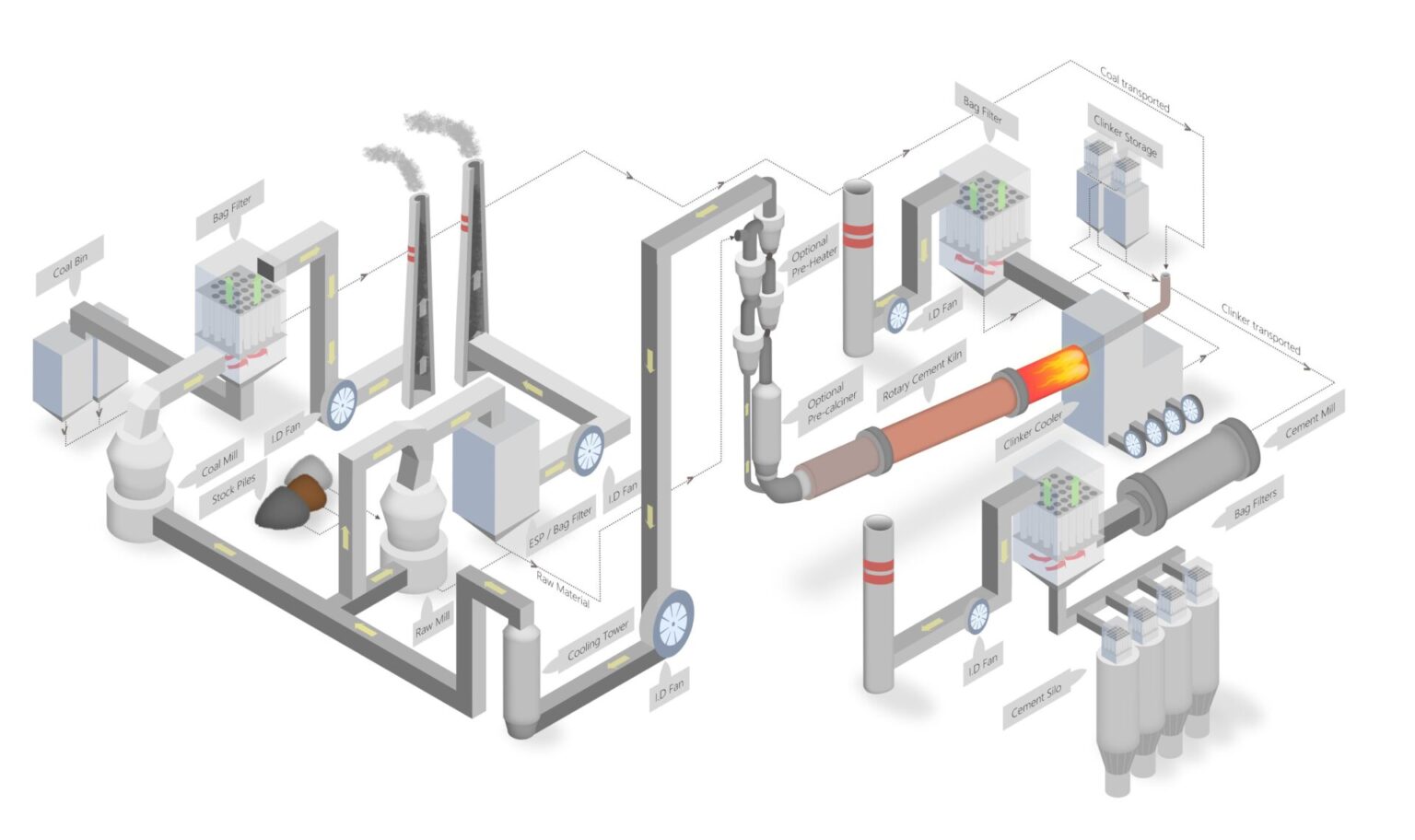

Cement plants are some of the most emission-intensive industrial facilities, producing large volumes of pollutants during the manufacturing process. Key emissions from cement production include nitrogen oxides (NOx), sulphur oxides (SOx), carbon monoxide (CO), carbon dioxide (CO₂), particulate matter (PM), and volatile organic compounds (VOCs). The continuous monitoring of these emissions is not only essential for regulatory compliance but also critical for reducing environmental impact and optimizing plant operations.

CEMS in Cement Plants: A Necessity for Compliance and Efficiency

Continuous Emission Monitoring Systems (CEMS) play a vital role in the cement industry by providing real-time data on these emissions. CEMS are used to measure pollutants at various points in the production process, including kilns, preheaters, and clinker coolers, where most emissions occur due to the combustion of fossil fuels and raw material processing.

For cement plants, staying compliant with stringent environmental regulations is a priority. CEMS helps operators track emissions closely, ensuring that pollutant levels remain within allowable limits and avoiding penalties or plant shutdowns. Beyond compliance, CEMS data allows cement plants to fine-tune their processes, reducing energy consumption and minimizing emissions, which in turn helps to reduce operational costs.

Why CODEL’s CEMS Are a Perfect Fit for Cement Plants

CODEL International Ltd. offers state-of-the-art CEMS designed to meet the specific challenges faced by the cement industry. Our emission monitoring systems are robust, reliable, and designed to operate in the harsh conditions found in cement plants. The high-temperature environments, heavy dust, and particulate matter typical of cement manufacturing require CEMS that can withstand these challenges without sacrificing accuracy or performance.

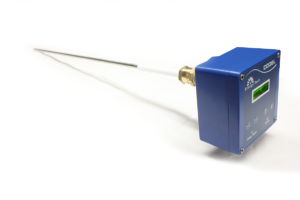

Products like CODEL’s EnergyTech 301 dust monitor are particularly well-suited for cement plants. Using proven triboelectric technology, the EnergyTech 301 provides highly accurate, real-time measurement of particulate matter. With minimal maintenance requirements, no critical alignment, and easy installation, it offers a cost-effective solution for monitoring dust emissions in smaller duct sizes—common in cement plant operations.

CODEL’s CEMS solutions provide continuous, real-time monitoring of critical pollutants such as NOx, SOx, CO, and particulate matter, ensuring compliance with local and international environmental regulations. By utilizing advanced sensor technology, CODEL’s monitors deliver precise measurements even in high-dust environments, helping cement plants reduce emissions and improve efficiency.

In addition, CODEL’s emission monitors offer detailed reporting and analytics, allowing operators to gain valuable insights into their plant’s emissions profile. This data can be used to make informed decisions about process optimization, energy efficiency, and pollution control strategies, all of which contribute to more sustainable and cost-effective cement production.

Suitable Products

The EnergyTech 301 is a low cost tribo electric dust monitor using well-proven technology providing accurate and rapid results.

Dust

Diagram Download

Looking for a manual?

Please contact us below and we will be happy to help you.