Monitoreo del colector de polvo

O que é monitoramento de poeira?

O monitoramento de poeira se refere ao processo de detecção e medição de material particulado transportado pelo ar em ambientes industriais. A poeira é um subproduto de várias atividades industriais, como combustão, fabricação, mineração e reciclagem, e pode representar riscos significativos para a saúde do trabalhador e para o meio ambiente. Os sistemas de monitoramento de poeira são projetados para rastrear continuamente as emissões de poeira e garantir a conformidade com os padrões ambientais, ao mesmo tempo em que ajudam a proteger os funcionários de problemas respiratórios, evitar explosões de poeira e manter condições operacionais ideais. Esses sistemas fornecem dados em tempo real, permitindo que os operadores identifiquem problemas potenciais, otimizem os processos de coleta de poeira e tomem as medidas necessárias para minimizar a exposição e a poluição.

Nossa linha de monitores de poeira

A CODEL oferece uma gama abrangente de soluções avançadas de monitoramento de poeira, projetadas para atender às diversas necessidades de indústrias que lidam com material particulado significativo no ar. Nossos monitores de poeira usam tecnologia de ponta para medir com precisão as emissões de partículas em tempo real, garantindo a conformidade com as regulamentações ambientais e aumentando a eficiência operacional. Com sistemas personalizados para geração de energia, marcenaria, mineração, produção de cimento e reciclagem, a CODEL fornece soluções confiáveis que ajudam a mitigar os efeitos nocivos das emissões de poeira, proteger a saúde dos trabalhadores e manter um ambiente de trabalho mais limpo e seguro.

Por que é importante usar monitores de poeira?

O monitoramento de poeira é essencial em vários setores por vários motivos principais:

Saúde e Segurança: A poeira pode causar problemas respiratórios, como asma e bronquite, e pode levar a sérios problemas de saúde se inalada por longos períodos. Em ambientes industriais, monitorar os níveis de poeira ajuda a identificar condições perigosas antes que elas representem riscos significativos à saúde dos trabalhadores.

Conformidade regulatória: Muitas indústrias são obrigadas a cumprir com regulamentações ambientais rigorosas sobre emissões de partículas. Os monitores de poeira garantem a conformidade fornecendo dados precisos e em tempo real sobre os níveis de emissão, reduzindo o risco de multas ou problemas legais devido à não conformidade.

Proteção Ambiental: Emissões descontroladas de poeira contribuem para a poluição do ar, o que pode impactar negativamente a qualidade do ar e o ambiente ao redor. O monitoramento de poeira ajuda a minimizar os danos ambientais ao garantir que os sistemas de coleta de poeira estejam funcionando de forma eficiente e que as emissões sejam mantidas dentro dos limites permitidos.

Eficiência Operacional: Ao monitorar continuamente as emissões de poeira, os operadores podem otimizar seus sistemas de controle de poeira, garantindo que estejam trabalhando com eficiência máxima. Isso ajuda a minimizar o tempo de inatividade, reduzir os custos de manutenção e melhorar o desempenho geral das operações industriais.

Prevenção de Explosões: Em algumas indústrias, partículas de poeira podem ser altamente explosivas. O monitoramento de poeira é essencial para evitar explosões de poeira, garantindo que os níveis de poeira sejam controlados e estejam dentro de limites seguros.

Por que escolher os produtos da CODEL para monitoramento de poeira?

A CODEL fornece soluções de monitoramento de poeira confiáveis e de alta qualidade para vários setores. Veja por que nossos produtos se destacam:

Soluções específicas para a indústria: A CODEL oferece sistemas de monitoramento de poeira personalizados, projetados para atender às necessidades exclusivas de diferentes indústrias, incluindo geração de energia, marcenaria, mineração, produção de cimento e reciclagem. Nossos sistemas garantem a conformidade com regulamentações específicas da indústria e melhoram a qualidade do ar e a segurança.

Precisão e confiabilidade: Nossos monitores de poeira são equipados com sensores avançados e tecnologias de medição que fornecem dados precisos e em tempo real. Isso garante a detecção confiável dos níveis de poeira e ajuda os operadores a tomar medidas proativas para controlar as emissões e manter um ambiente de trabalho seguro.

Fácil integração: os sistemas de monitoramento de poeira da CODEL são projetados para fácil integração em sistemas de coleta e filtragem de poeira existentes. Isso minimiza a interrupção operacional e garante um processo de instalação tranquilo.

Durabilidade e baixa manutenção: Nossos monitores são desenvolvidos para suportar ambientes industriais adversos e exigem manutenção mínima, reduzindo custos operacionais e tempo de inatividade a longo prazo.

Compliance and Reporting: With CODEL’s dust monitoring systems, you can easily track emissions and generate detailed reports for regulatory compliance. This ensures adherence to environmental standards and avoids potential fines.

Support and Expertise: CODEL offers expert support throughout the installation, operation, and maintenance of your dust monitoring systems. Our team is dedicated to ensuring your systems perform optimally and help you meet your environmental and safety goals.

By choosing CODEL, you are investing in reliable, efficient, and cost-effective dust monitoring solutions that protect worker health, minimize environmental impact, and ensure compliance with regulatory requirements.

Our Range of Dust Collector Monitors Include:

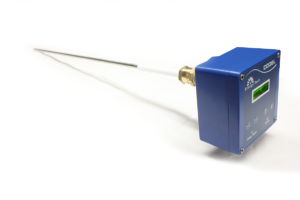

El EnergyTech 301 es un monitor de polvo eléctrico tribo de bajo costo que utiliza tecnología comprobada y proporciona resultados precisos y rápidos.

Polvo

Un dispositivo óptico de un solo paso que utiliza luz visible para medir la opacidad y el polvo dentro de los gases de combustión.

Opacidad / Polvo

El analizador GCEM40 es un dispositivo in situ rentable, de bajo mantenimiento y diseñado tanto para el control de procesos como para la monitorización de emisiones.

CO, NOx, SO2, HCl, CH4, CO2 y H2O

El analizador de gases multicanal de extracción en caliente GCEM40E es el monitor continuo de emisiones comprobado en la industria de CODEL para aplicaciones difíciles

CO, NOx, SO2, HCl, CH4, CO2 y H2O

Haga una pregunta

Para obtener más información sobre cualquiera de nuestros productos, rellene nuestro formulario de consulta y un miembro del personal le responderá lo antes posible.

También puede llamar al: +44(0)1629 814351