The Evolution of CODELS Continuous Emission Monitoring Systems (CEMS)

With nearly 40 years of expertise in the control and instrumentation sector, CODEL International has been instrumental in the evolution of Continuous Emission Monitors (CEMS). This journey has been driven by technological advancements and a growing emphasis on environmental protection, with CODEL consistently at the forefront of developing innovative and reliable monitoring solutions.

Early Monitoring Solutions

Emission monitoring began as a manual and labour-intensive process that relied on basic sampling methods, often leading to inaccuracies. Early CEMS were simple, provided limited data, and required significant human intervention. Despite these challenges, these systems highlighted the need for continuous and automated monitoring, setting the stage for future advancements.

Technological Advancements

Technological progress greatly enhanced the capabilities of CEMS. The introduction of sophisticated sensors, improved data processing, and automation transformed these systems into highly accurate tools. CODEL integrated these innovations, incorporating real-time measurements, powerful data processors, and automated calibration to maintain consistent accuracy and reduce manual involvement.

CODEL’s Innovations

CODEL has consistently expanded the potential of CEMS technology. By developing modular systems tailored to diverse industrial needs, CODEL’s solutions have become essential in industries ranging from power plants to waste incineration facilities. These systems include advanced emissions reporting, helping industries comply with regulations and improve their processes. CODEL’s focus on reliability has led to systems with redundancies and fail-safes, making them trusted in the field.

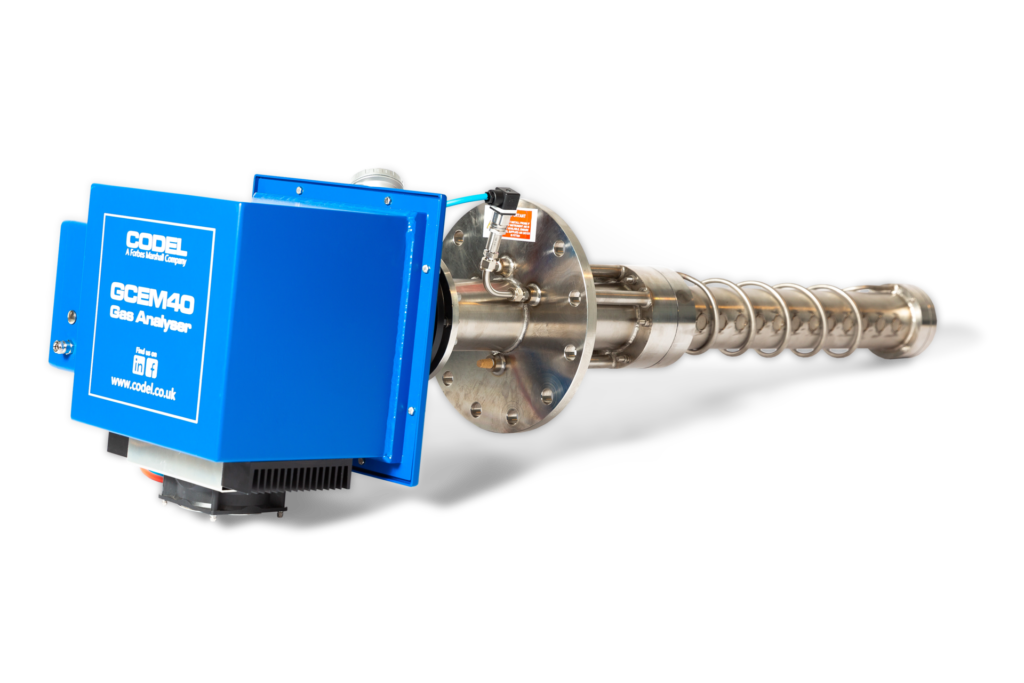

An Example: The Evolution from GCEM4000 to GCEM40

The shift from the GCEM4000 to the GCEM40 series showcases CODEL’s dedication to innovation. The GCEM4000, a robust multi-channel analyser using Non-Dispersive Infrared Absorption (NDIR) technology, excelled in high dust environments and automated performance verification, making it ideal for challenging conditions. The GCEM40 series builds on these strengths with advanced infrared spectroscopy, in-situ stainless steel probes, and enhanced pollutant measurement capabilities. This newer model offers greater accuracy, flexibility, and reduced maintenance, providing a more efficient solution for emissions monitoring and process control at a competitive price.

The Future of Emission Monitoring with CODEL CLOUD

As we look ahead, CODEL is set to transform emission monitoring with CODEL CLOUD, our advanced online software platform. Integrating AI and enhanced automation, CODEL CLOUD changes how users manage emission data. This platform offers real-time insights, historical reporting, and preventative maintenance notifications accessible from anywhere. It also simplifies site installations, reduces cabling, and provides automated diagnostic logging to enhance decision-making and efficiency. By linking CEMS data to CODEL CLOUD, industries can streamline operations, stay ahead of environmental standards, and fully embrace the future of emissions control.