Soporte en todo el mundo

Over 25 distributors and support centres worldwide

Contratos de mantenimiento flexibles

Contratos específicos de planta a medida con soporte las 24 horas

30 years experience

Desarrollando, fabricando e instalando

Waste to Energy Power Plants: Navigating Continuous Emissions Monitoring Regulations

Waste to Energy (WtE) power plants stand as beacons of sustainability, offering a dual benefit of waste management and energy generation. However, their operations are intricately tied to environmental regulations, particularly concerning continuous emissions monitoring (CEM). Let’s delve into the world of WtE plants and explore the stringent regulations governing their emissions monitoring.

The Role of Waste to Energy (WtE) Power Plants

Waste to Energy power plants play a pivotal role in converting various forms of waste into energy, reducing the strain on landfills, and offering a renewable energy source. These plants utilize advanced technologies to convert municipal, industrial, or agricultural waste into electricity, heat, or fuel, contributing to a circular economy.

Emissions from waste combustion can contain pollutants like nitrogen oxides (NOx), Sulphur Dioxide (SO2), Carbon Monoxide (CO), particulate matter, and heavy metals. Continuous Monitoring of these emissions is crucial to ensure compliance with stringent environmental regulations.

Regulations Governing Emissions Monitoring in WtE Plants

EPA Regulations in the United States: The Environmental Protection Agency (EPA) in the US imposes strict regulations on emissions from WtE plants under the Clean Air Act. It mandates continuous monitoring of various pollutants and sets emission limits that facilities must comply with.

EU Directives: In the European Union, directives such as the Industrial Emissions Directive (IED) set emission limit values and require continuous monitoring of key pollutants from WtE facilities to protect human health and the environment.

International Standards: Internationally, standards like the International Organization for Standardization (ISO) provide guidelines for emissions monitoring and control in WtE plants, ensuring a global framework for environmental compliance.

Continuous Emissions Monitoring Systems (CEMS) in WtE Plants

CEMS are instrumental in keeping emissions in check by constantly monitoring various pollutants released during the waste combustion process. These systems employ advanced analysers, sensors, and monitoring equipment to measure emissions in real-time.

Gas Analysers: Measure concentrations of pollutants like NOx, SO2, CO, and oxygen levels in the flue gases.

Particulate Monitors: Monitor and report levels of particulate matter released during combustion.

Continuous Opacity Monitors: Gauge the opacity of the flue gases, indicating the presence of particulate matter.

Challenges and Advancements in CEM Technologies

WtE plants face challenges in meeting stringent emissions regulations while ensuring optimal energy generation. Balancing efficiency, cost-effectiveness, and compliance remains a constant challenge. However, advancements in emissions monitoring technologies, such as sensor accuracy, data analytics, and predictive modelling, help reduce environmental impact.

Conclusion: A Sustainable Path Forward

Continuous emissions monitoring regulations for Waste-to-Energy power plants represent a commitment to environmental stewardship and public health. By adhering to these stringent regulations and embracing technological advancements, WtE facilities can continue to play a crucial role in waste management while contributing to sustainable energy production. As technology evolves, a harmonious balance between energy generation and emissions control will pave the way for a cleaner and more sustainable future.

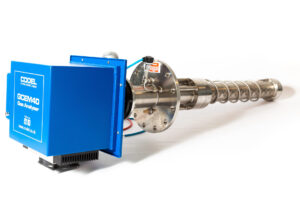

The VCEM5000/5100 represents the latest generation of CODEL’s unique flow monitors.