Introduction to Continuous Emission Monitoring Systems (CEMS): How They Work and Why They Matter

Introduction to CEMS: In an age where environmental concerns are increasingly at the forefront of industrial and public discourse, the need for effective pollution control and regulatory compliance has never been greater. Consequently, Continuous Emission Monitoring Systems (CEMS) have emerged as vital tools in this quest. These systems offer robust solutions for tracking and managing industrial emissions. At CODEL International Ltd., we specialize in providing state-of-the-art CEMS to industries worldwide. Thus, we help them meet regulatory standards and protect the environment. Let’s explore what CEMS are, how they work, and why they matter.

What Are Continuous Emission Monitoring Systems (CEMS)?

Continuous Emission Monitoring Systems (CEMS) are advanced technologies designed to continuously collect, record, and report data on the emissions produced by industrial processes. Specifically, these systems measure various pollutants, including nitrogen oxides (NOx), sulfur dioxide (SO2), carbon dioxide (CO2), particulate matter (PM), and volatile organic compounds (VOCs). As a result, they ensure that emissions stay within regulatory limits.

How Do CEMS Work?

CEMS operate through a series of steps involving detection, data collection, and analysis:

- Detection: Firstly, in the detection phase, CEMS use sensors and analysers to identify specific pollutants in the flue gas emitted from industrial stacks. These sensors can utilize different detection methods depending on the type of pollutant being monitored.

- Data Collection: Next, during the data collection phase, the detected emissions are continuously sampled and analysed. Modern CEMS are equipped with sophisticated data acquisition systems that gather real-time data on various emission parameters, such as concentration levels, flow rates, and gas temperatures.

- Data Analysis and Reporting: Finally, in the data analysis and reporting phase, the collected data is processed and analyzed to ensure compliance with environmental regulations. Moreover, advanced CEMS can generate detailed reports and alerts, enabling operators to take corrective actions if emission levels exceed permissible limits. Additionally, these systems often include remote monitoring capabilities, allowing for centralized data management and reporting.

Why Do CEMS Matter?

The importance of CEMS extends beyond mere regulatory compliance. Here are several reasons why CEMS are crucial:

- Regulatory Compliance: Adhering to environmental regulations is mandatory for industrial facilities. Consequently, CEMS provide accurate and reliable data that ensure compliance with local, national, and international emission standards. This helps businesses avoid fines, legal actions, and operational shutdowns.

- Environmental Protection: By continuously monitoring and controlling emissions, CEMS play a critical role in reducing air pollution and protecting the environment. This proactive approach helps mitigate the harmful impacts of industrial activities on ecosystems and public health.

- Operational Efficiency: Additionally, CEMS offer insights into the efficiency of industrial processes, enabling operators to optimize performance. Improved operational efficiency not only lowers emissions but also cuts costs, thereby contributing to better profitability.

- Public Accountability: Moreover, transparency in reporting emissions data fosters public trust and accountability. By using CEMS, companies can demonstrate their commitment to environmental stewardship and corporate social responsibility, thus enhancing their reputation among stakeholders and the community.

- Future-Proofing: Lastly, as environmental regulations become increasingly stringent, investing in CEMS ensures that businesses stay ahead of compliance requirements. This future-proofing approach protects long-term operational viability and supports sustainable growth.

Conclusion

Introduction to CEMS: Continuous Emission Monitoring Systems (CEMS) are indispensable tools for industries committed to regulatory compliance and environmental protection. At CODEL International Ltd., we provide cutting-edge CEMS solutions tailored to meet the specific needs of various industries. By leveraging our expertise and innovative technologies, businesses can monitor their emissions effectively. Consequently, they can optimize their operations and, in turn, contribute to a sustainable future.

If you’re ready to learn more about how CEMS can benefit your operations, explore our comprehensive range of stack emission monitoring solutions at CODEL International Ltd. Take the first step towards a cleaner, greener tomorrow.

The DCEM2100 dust monitor provides a continuous measurement of opacity or dust concentration in flue gases by continuously measuring the transmissivity of visible light across a process duct or stack.

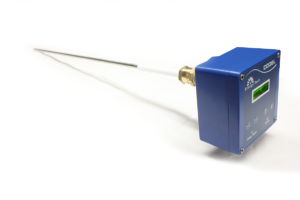

The EnergyTech 301 is a low cost dust monitor using well-proven tribo electric technology providing accurate and rapid results. The EnergyTech 301 requires no critical alignment and has no optical surfaces to keep clean.