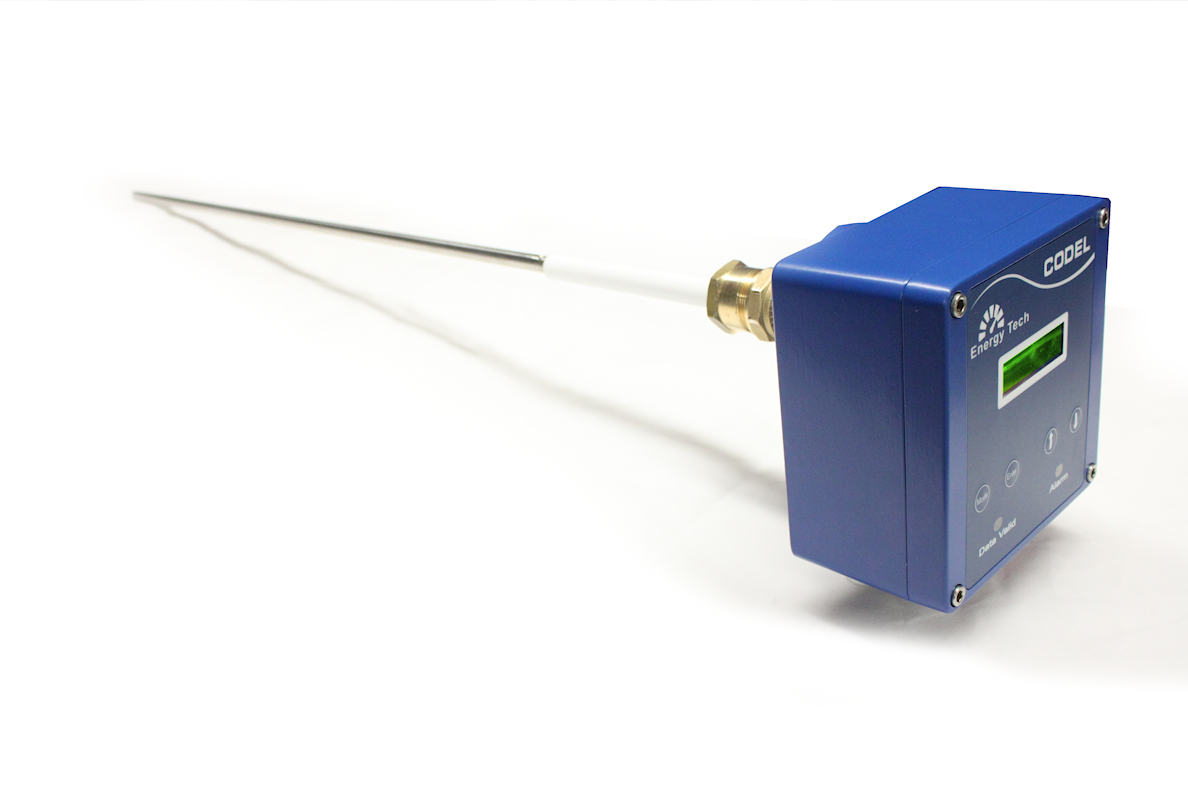

EnergyTech 301

Applications

- Power Generation

- Mining and Quarrying

- Cement and Concrete Production

- Recycling and Waste Management

Features & Benefits

- Direct sensing method, actual particulate concentration

- Automated online zero and span checking facility.

- Integrated calibration function for mg/m3 output.

- Easy installation with minimal maintenance required.