Worldwide Support

Over 25 distributors and support centres worldwide

Flexible maintenance contracts

Tailor made plant specific contracts with 24Hr Support

30 years experience

Developing, manufacturing and installing

Monitoring Emissions Across Industries: The Vital Role of CEMs

Continuous Emissions Monitoring Systems (CEMs) are pivotal across various industries for tracking and mitigating emissions to meet stringent environmental standards. Let’s explore a range of manufacturing plants, power stations, and even carbon black facilities where CEMs play a crucial role in monitoring emissions:

Coal-fired Power Plants

These plants are significant contributors to air pollution due to the combustion of coal, emitting pollutants such as sulphur dioxide (SO2), nitrogen oxides (NOx), and particulate matter. Continuous Emissions Monitoring Systems (CEMs) are essential in coal-fired power plants to continuously monitor these emissions and ensure compliance with stringent environmental regulations.

Natural Gas Power Plants

While natural gas is considered a cleaner alternative to coal, natural gas plants still emit pollutants. CEMs play a crucial role in these plants by continuously monitoring emissions and helping operators optimize combustion efficiency to minimize environmental impact. Additionally, CEMs aid in detecting any malfunctions or leaks in the system, ensuring the safe operation of natural gas power plants.

Oil Refineries

Oil refineries process crude oil into various petroleum products, emitting pollutants such as volatile organic compounds, sulphur compounds, and particulate. CEMs are indispensable in oil refineries for monitoring these emissions and ensuring compliance with environmental regulations. By providing real-time data on emission levels, CEMs help operators identify areas for improvement and implement measures to reduce pollution.

Chemical Manufacturing Plants

Chemical manufacturing plants produce a wide range of products, emitting pollutants such as VOCs and hazardous air pollutants (HAPs). CEMs are vital in these plants for monitoring emissions and ensuring regulatory compliance. By continuously monitoring emission levels, CEMs help chemical plant operators identify sources of pollution and implement measures to minimize environmental impact and protect public health.

Steel Mills

Steel manufacturing processes emit pollutants such as particulate matter and greenhouse gases (GHGs) like CO2. CEMs are instrumental in steel mills for monitoring these emissions and ensuring compliance with environmental regulations. By providing real-time data on emission levels, CEMs enable steel mill operators to optimize production processes, reduce energy consumption, and minimize pollution.

Cement Plants

Cement manufacturing involves processes that emit pollutants such as NOx, SO2, and CO2. CEMs are crucial in cement plants for monitoring these emissions and ensuring compliance with environmental regulations. CEMs help cement plant operators optimize production processes, reduce energy consumption, and minimize pollution emissions.

Waste Incineration Plants

Waste incineration plants combust municipal solid waste, emitting pollutants such as dioxins, furans, and heavy metals. CEMs are essential in these plants for monitoring emissions and ensuring compliance with environmental regulations. By providing real-time data on emission levels, CEMs help waste incineration plant operators optimize combustion processes, reduce pollution emissions, and minimize environmental impact.

Pulp and Paper Mills

Pulp and paper manufacturing processes emit pollutants such as particulate matter and VOCs. CEMs are indispensable in pulp and paper mills for monitoring these emissions and ensuring compliance with environmental regulations. By continuously monitoring emission levels, CEMs help pulp and paper mill operators identify sources of pollution and implement measures to minimize environmental impact and protect public health.

Carbon Black Plants

Carbon black plants produce carbon black, emitting particulate matter and other pollutants during production. CEMs are essential in these plants for monitoring emissions and ensuring compliance with environmental regulations. By providing real-time data on emission levels, CEMs help carbon black plant operators optimize production processes, reduce pollution emissions, and minimize environmental impact.

Across these diverse sectors, CEMs serve as indispensable tools for real-time emission monitoring, enabling industries to uphold environmental standards, reduce pollution, and foster sustainable practices.

The DCEM2100 dust monitor provides a continuous measurement of opacity or dust concentration in flue gases by continuously measuring the transmissivity of visible light across a process duct or stack.

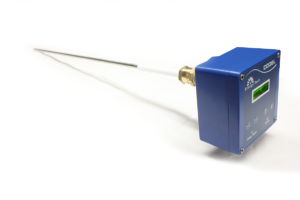

The EnergyTech 301 is a low cost dust monitor using well-proven tribo electric technology providing accurate and rapid results. The EnergyTech 301 requires no critical alignment and has no optical surfaces to keep clean.