Coal Mill Monitoring

What is Coal Mill Monitoring?

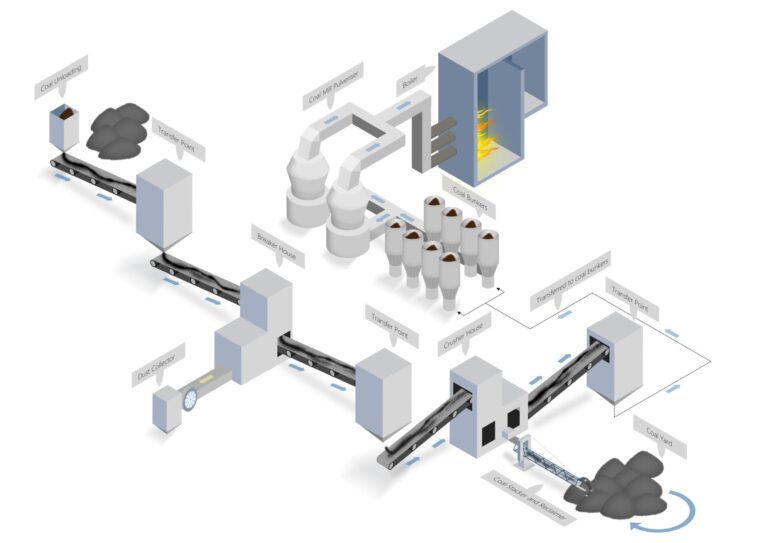

Coal mill monitoring is a critical safety practice used in industries relying on pulverized coal for energy production. Coal’s propensity for spontaneous combustion poses significant risks, with coal fires often originating in hotspots when coal absorbs oxygen and generates heat. If undetected, these hotspots can lead to smouldering fires, releasing dangerous levels of carbon monoxide (CO). The continuous measurement of CO levels in coal mills, silos, and other handling systems is a proven method for early detection of fires, even before surface temperatures rise. This proactive monitoring prevents catastrophic damage to equipment and ensures the safety of personnel.

Our Range of Coal Mill Monitors Include:

- CO

- O2

Why Is It Important to Monitor Coal Mills?

Measuring in coal mills is critical for maintaining safe, efficient, and environmentally responsible operations. Coal mills, essential in pulverized coal systems, can pose serious risks if emissions such as carbon monoxide (CO) are not carefully monitored. CO build-up, often a precursor to smouldering fires, signals potential combustion hazards. Early detection of CO through continuous monitoring allows operators to take prompt action, mitigating the risk of explosions and ensuring the safety of personnel and equipment.

In addition to safety, emission monitoring is key to regulatory compliance and environmental stewardship. Coal combustion produces pollutants such as sulphur dioxide (SO₂), nitrogen oxides (NOx) and particulate matter (PM), which must be controlled to meet environmental standards. Monitoring these emissions helps plants minimize their environmental impact while avoiding regulatory fines.

Effective emission monitoring in coal mills also improves operational efficiency by reducing downtime, optimizing combustion processes, and preventing costly equipment damage. By ensuring safe and sustainable energy production, emission monitoring supports both the industry’s operational goals and its commitment to environmental responsibility.

Why Choose CODEL's Products for Coal Mill Monitoring?

CODEL’s products for coal mill monitoring offer advanced technology and reliable performance to meet the stringent demands of coal-fired power plants. With continuous CO monitoring, CODEL’s systems provide real-time data on gas concentrations, allowing for immediate detection of potential hazards and enabling swift corrective actions. CODEL’s monitoring solutions are equipped with alarm and alert systems to notify operators of any anomalies, ensuring a safe working environment and preventing dangerous situations. The data logging and reporting capabilities of CODEL’s products facilitate comprehensive analysis and compliance with regulatory requirements, providing valuable insights into operational efficiency and emissions control. CODEL’s products are designed for easy installation and minimal maintenance, offering a cost-effective solution for coal mill monitoring. By choosing CODEL’s monitoring systems, operators can ensure the highest standards of safety, environmental compliance, and operational excellence in coal mill operations.

Diagram Download

Looking for a manual?

Please contact us below and we will be happy to help you.

Our range of Coal Mill Monitors:

Early detection of fires in coal pulverising mills is essential to avoid catastrophic damage to plant and to avert the threat of injury to personnel

CO & O2

As an alternative to the EC CELL EnergyTech 201 analyser, the EnergyTech 202 utilises an infrared optical bench for the measurement of CO.

CO

The EnergyTech 203 utilises the same infrared optical bench as the EnegyTech 202 but includes a Zircona based oxygen measurement.

CO & O2

Ask a question

For further information on any of our products, please complete our enquiry form and a member of staff will respond as soon as possible.

You can also call: +44(0)1629 814351