The requirement for SCR & SNCR (DeNOx)

DeNOx SCR and SNCR Monitoring

For decades, coal has been the primary fuel used by power stations globally, despite its significant environmental impact. As environmental regulations in regions such as Europe, China, and India have become stricter, coal-fired power stations are facing increasing challenges and costs to comply with new emission limits. To meet these regulations, many power plants are turning to advanced technologies like Selective Catalytic Reduction (SCR) and Selective Non-Catalytic Reduction (SNCR). These technologies are proven to significantly reduce nitrogen oxides (NOx) emissions, contributing to cleaner air and safer environments.

How SCR and SNCR Work

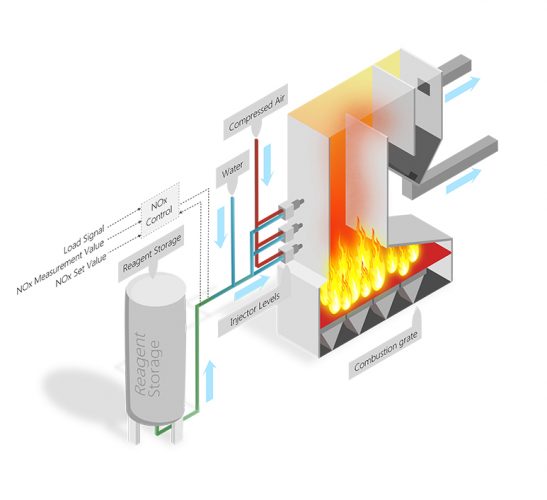

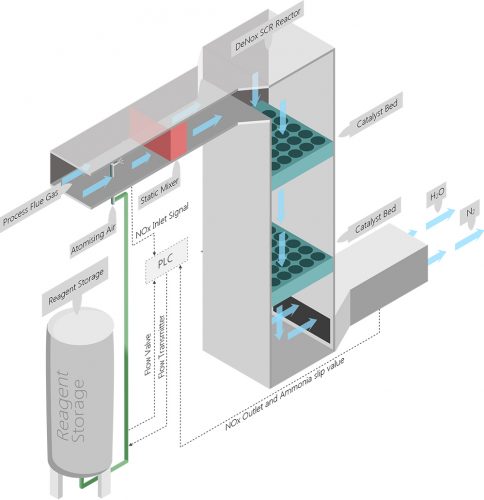

During the combustion process, nitrogen reacts with oxygen at high temperatures to form nitrogen oxides (NOx), which include nitrogen monoxide (NO) and nitrogen dioxide (NO2). To meet stringent NOx emission limits, power plants implement DeNOx processes. These processes typically involve reacting nitrogen oxides in the flue gas with ammonia or urea at elevated temperatures. Ammonia or urea reacts with NO and NO2 to convert them into nitrogen (N2), water vapor (H2O), and, in the case of urea, carbon dioxide (CO2). SCR systems are commonly used in large coal-fired power stations, while SNCR is often deployed in smaller plants or those using Circulating Fluidized Bed (CFB) boilers to achieve similar reductions in NOx emissions.

The Environmental and Health Benefits of SCR and SNCR

By implementing SCR and SNCR technologies, combustion plants can significantly reduce NOx emissions, which in turn mitigates environmental issues such as smog, acid rain, and visibility reduction. NOx emissions are also a significant contributor to respiratory health problems, so reducing them is a key step in improving public health. These DeNOx technologies not only help power stations comply with ever-stricter environmental regulations, but they also support sustainable energy practices by reducing the environmental footprint of coal-fired power generation.

What we do

Continuous monitoring is essential for managing SCR and SNCR systems effectively. To ensure these emissions control technologies are operating efficiently and meeting compliance standards, CODEL provides a comprehensive range of advanced products designed to monitor both input and output gases, as well as flow and dust emissions. CODEL’s cutting-edge monitoring solutions deliver accurate and reliable data, enabling operators to optimize SCR and SNCR system performance while minimizing environmental impact. With these state-of-the-art technologies, industries can maintain sustainable emissions control practices, improve operational efficiency, and stay compliant with environmental regulations.

SNCR Process

SCR Process

Diagram Download

Looking for a manual?

Please contact us below and we will be happy to help you.

Suitable Products

The DCEM2100 is a dual-pass transmissometer configured for the continuous measurement of opacity and dust concentration in flue gases.

CODEL’s unique flow monitors measure the velocity of stack gases using a highly accurate time of flight measurement that is derived from a cross correlation analysis of the infra-red emissions of the turbulent gas.

Gas Flow

The GCEM40E hot extractive multi-channel gas analyser is CODEL’s industry-proven continuous emissions monitor for difficult applications

CO, NOx, SO2, HCl, CH4, CO2 & H2O

The GCEM40 analyser is an in-situ device which is cost-effective, low maintenance and designed both for process control and emissions monitoring.

CO, NOx, SO2, HCl, CH4, CO2 & H2O

Ask a question

For further information on any of our products, please complete our enquiry form and a member of staff will respond as soon as possible.

You can also call: +44(0)1629 814351