Dust Collector Monitoring

What is Dust Monitoring?

Dust monitoring refers to the process of detecting and measuring airborne particulate matter in industrial environments. Dust is a by-product of various industrial activities, such as combustion, manufacturing, mining, and recycling, and can pose significant risks to both worker health and the environment. Dust monitoring systems are designed to continuously track dust emissions and ensure compliance with environmental standards, while also helping to protect employees from respiratory issues, prevent dust explosions, and maintain optimal operational conditions. These systems provide real-time data, allowing operators to identify potential problems, optimize dust collection processes, and take necessary actions to minimize exposure and pollution.

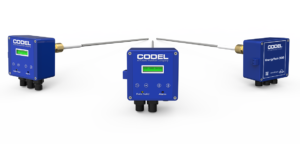

Our Range of Dust Monitors

CODEL offers a comprehensive range of advanced dust monitoring solutions, designed to meet the diverse needs of industries that deal with significant airborne particulate matter. Our dust monitors use cutting-edge technology to accurately measure particulate emissions in real-time, ensuring compliance with environmental regulations and enhancing operational efficiency. With systems tailored for power generation, woodworking, mining, cement production, and recycling, CODEL provides reliable solutions that help mitigate the harmful effects of dust emissions, protect worker health, and maintain a cleaner, safer working environment.

Why Is It Important to Use Dust Monitors?

Dust monitoring is essential across various industries for several key reasons:

Health and Safety: Dust can cause respiratory issues, such as asthma and bronchitis, and may lead to serious health problems if inhaled over long periods. In industrial environments, monitoring dust levels helps identify hazardous conditions before they pose significant health risks to workers.

Regulatory Compliance: Many industries are required to comply with strict environmental regulations regarding particulate emissions. Dust monitors ensure compliance by providing accurate, real-time data on emission levels, reducing the risk of fines or legal issues due to non-compliance.

Environmental Protection: Uncontrolled dust emissions contribute to air pollution, which can negatively impact air quality and the surrounding environment. Dust monitoring helps minimize environmental damage by ensuring that dust collection systems are functioning efficiently and that emissions are kept within permissible limits.

Operational Efficiency: By continuously monitoring dust emissions, operators can optimize their dust control systems, ensuring they are working at peak efficiency. This helps minimize downtime, reduce maintenance costs, and improve the overall performance of industrial operations.

Preventing Explosions: In some industries, dust particles can be highly explosive. Dust monitoring is essential for preventing dust explosions by ensuring dust levels are controlled and within safe limits.

Why Choose CODEL's Products for Dust Monitoring?

CODEL provides high-quality, reliable dust monitoring solutions for various industries. Here’s why our products stand out:

Industry-Specific Solutions: CODEL offers tailored dust monitoring systems designed to meet the unique needs of different industries, including power generation, woodworking, mining, cement production, and recycling. Our systems ensure compliance with industry-specific regulations and enhance air quality and safety.

Precision and Reliability: Our dust monitors are equipped with advanced sensors and measurement technologies that provide accurate, real-time data. This ensures reliable detection of dust levels and helps operators take proactive steps to control emissions and maintain a safe working environment.

Easy Integration: CODEL’s dust monitoring systems are designed for easy integration into existing dust collection and filtration systems. This minimizes operational disruption and ensures a smooth installation process.

Durability and Low Maintenance: Our monitors are built to withstand harsh industrial environments and require minimal maintenance, reducing long-term operating costs and downtime.

Compliance and Reporting: With CODEL’s dust monitoring systems, you can easily track emissions and generate detailed reports for regulatory compliance. This ensures adherence to environmental standards and avoids potential fines.

Support and Expertise: CODEL offers expert support throughout the installation, operation, and maintenance of your dust monitoring systems. Our team is dedicated to ensuring your systems perform optimally and help you meet your environmental and safety goals.

By choosing CODEL, you are investing in reliable, efficient, and cost-effective dust monitoring solutions that protect worker health, minimize environmental impact, and ensure compliance with regulatory requirements.

Our Range of Dust Collector Monitors Include:

A complete range of triboelectric dust monitors, from reliable QAL1-certified Emissions Monitoring to affordable, accurate bag filter leak detection.

Dust

A single-pass optical device which uses visible light to measure the opacity and dust within the flue gas.

Opacity / Dust

The GCEM40 analyser is an in-situ device which is cost-effective, low maintenance and designed both for process control and emissions monitoring.

CO, NOx, SO2, HCl, CH4, CO2 & H2O

The GCEM40E hot extractive multi-channel gas analyser is CODEL’s industry-proven continuous emissions monitor for difficult applications

CO, NOx, SO2, HCl, CH4, CO2 & H2O

Ask a question

For further information on any of our products, please complete our enquiry form and a member of staff will respond as soon as possible.

You can also call: +44(0)1629 814351