Flue Gas Desulphurisation (FGD)

FGD Gas, Dust, and Flow Monitoring

In industrial processes such as coal combustion, oil refining, waste incineration, and metal ore production, sulphur dioxide (SO2) is a major by-product. This compound poses significant risks to human health, contributes to acid rain, and degrades the environment. To address these concerns, Flue Gas Desulphurisation (FGD) technologies are employed to remove SO2 from flue gases before they are released into the atmosphere. FGD systems play a crucial role in reducing emissions, particularly for coal-fired power plants, which are either already equipped with SO2 scrubbers or in the process of retrofitting their systems to meet stringent environmental standards.

How FGD Systems Work

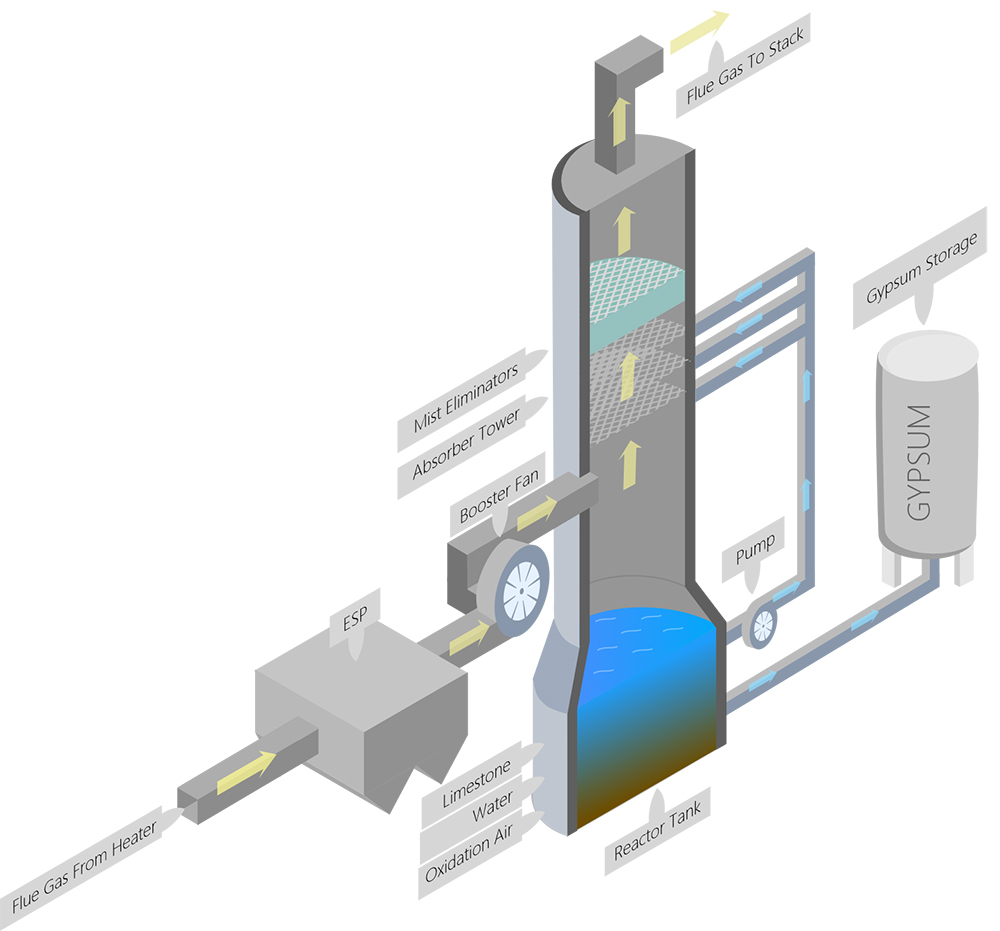

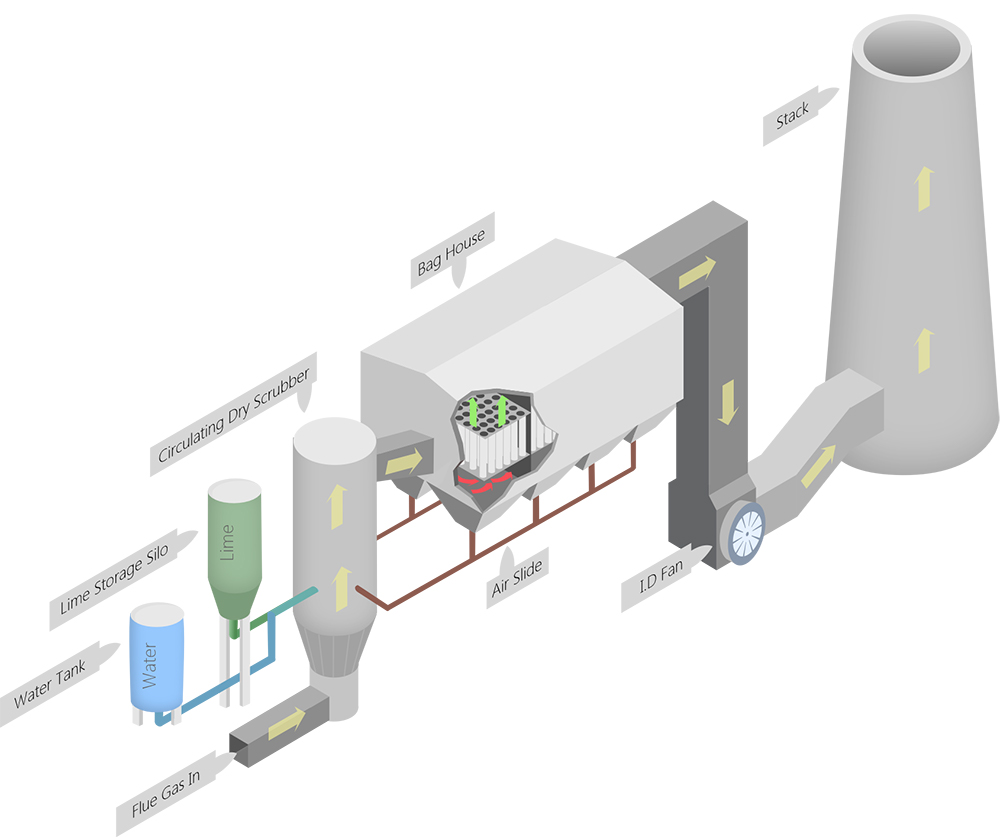

The process behind most SO2 removal methods involves spraying an alkali sorbent into the flue gas, which reacts with the acidic SO2 as well as other acidic gases like hydrogen chloride (HCl) and hydrogen fluoride (HF). The reaction neutralizes these pollutants, making them safer for the environment. The products of this reaction are then captured depending on the type of FGD system used. In dry FGD systems, the reaction products are captured by dust filters, while wet FGD systems use a gypsum slurry in a sump to precipitate and remove pollutants. Sea Water FGD systems treat and dispose of the reaction products safely into the sea after appropriate treatment.

The Role of Sorbents in FGD Systems

Limestone, lime, and hydrated lime are the most used sorbents in the desulphurization process due to their high effectiveness in neutralizing acidic components in flue gases. These materials play a vital role in reducing SO2 emissions and improving air quality. By efficiently removing harmful sulphur compounds, these sorbents contribute to a cleaner atmosphere and a more sustainable industrial process, helping industries meet both regulatory and environmental standards.

What We Do

Continuous monitoring is crucial to ensure FGD systems operate effectively and in compliance with environmental regulations. CODEL provides a range of advanced monitoring products designed to track both input and output gases, as well as flow and dust emissions. Using the latest technology, CODEL’s monitoring solutions deliver reliable, real-time data, helping operators optimize their FGD systems’ performance. By integrating CODEL’s systems into their operations, industries can reduce their environmental impact, maintain compliance, and ensure the continued efficiency of their emissions control systems, ultimately contributing to a cleaner, healthier environment.

Wet limestone FGD with open spray tower

Semi-Dry FGD, circulating dry scrubber

Suitable Products

The DCEM2100 is a dual-pass transmissometer configured for the continuous measurement of opacity and dust concentration in flue gases.

Diagram Download

Looking for a manual?

Please contact us below and we will be happy to help you.

The GCEM40 analyser is an in-situ device which is cost-effective, low maintenance and designed both for process control and emissions monitoring.

CO, NOx, SO2, HCl, CH4, CO2 & H2O

The GCEM40E hot extractive multi-channel gas analyser is CODEL’s industry-proven continuous emissions monitor for difficult applications

CO, NOx, SO2, HCl, CH4, CO2 & H2O

Ask a question

For further information on any of our products, please complete our enquiry form and a member of staff will respond as soon as possible.

You can also call: +44(0)1629 814351