Large & Small Combustion Plant

What Is Monitoring in Large and Small Combustion Plants?

Monitoring in combustion plants involves tracking and analysing emissions to ensure compliance with environmental regulations, optimize operational performance, and mitigate the environmental and health impacts of pollutants.

Small combustion plants typically include residential heating systems, small industrial boilers, and decentralized power generators. These systems often rely on periodic emissions checks and maintenance to minimize pollutants like carbon monoxide (CO), sulphur dioxide (SO₂), and particulate matter (PM).

Large combustion plants, such as power stations and industrial facilities, require advanced Continuous Emissions Monitoring Systems (CEMS). These systems measure pollutants like nitrogen oxides (NOx), volatile organic compounds (VOCs), and greenhouse gases in real-time, ensuring constant adherence to stringent environmental standards.

In both small and large combustion plants, the monitoring of emissions such as sulphur dioxide (SO2), nitrogen oxides (NOx), particulate matter (PM), carbon monoxide (CO), and volatile organic compounds (VOCs) is crucial. These pollutants can have significant adverse effects on local air quality and contribute to regional environmental issues such as acid rain, smog formation, and respiratory diseases.

For small combustion plants, monitoring is often focused on ensuring compliance with local emissions regulations and standards. This involves using portable or stationary monitoring devices to measure emissions during operation periods. Continuous monitoring may not be feasible due to scale and resource limitations, but periodic checks and maintenance of equipment are essential to minimize emissions and maintain compliance.

On the other hand, large combustion plants are typically subject to more stringent regulatory requirements and are equipped with continuous emissions monitoring systems (CEMS). CEMS continuously measure and record emissions data in real-time, providing accurate information on pollutant concentrations and ensuring immediate detection of any deviations from regulatory limits. This allows operators to take prompt corrective actions to mitigate emissions and maintain compliance with environmental regulations.

Our Range of Combustion Plant Monitors Include:

- CEMS for Large Combustion Plants: Delivering real-time monitoring of SO₂, NOx, PM, and VOCs to meet regulatory requirements.

- Portable Emissions Monitors for Small Combustion Plants: Cost-effective solutions for periodic compliance checks and operational maintenance.

- Advanced Analysers: Utilizing laser-based and electrochemical technologies for precision and reliability.

Why Is It Important to Measure Emissions in Small and Large Combustion Plants?

Emission monitoring is critical for maintaining air quality, safeguarding public health, and protecting the environment.

- For Small Combustion Plants:

Monitoring ensures compliance with local regulations and minimizes pollution in residential and small-scale industrial settings. It helps detect potential issues like incomplete combustion, reducing harmful gases like CO and VOCs.

- For Large Combustion Plants:

Continuous monitoring helps prevent regulatory breaches, optimize combustion processes, and minimize emissions of major pollutants. This is essential for reducing large-scale environmental impacts such as acid rain, smog, and greenhouse gas emissions.

Effective monitoring not only ensures regulatory compliance but also enhances operational efficiency and sustainability.

Why Choose CODEL’s Products for Small and Large Combustion Plant Monitoring?

CODEL delivers tailored solutions for monitoring emissions across all scales of combustion plants.

- For Small Combustion Plants:

CODEL offers cost-effective, portable monitoring systems that provide accurate data for periodic checks. These solutions ensure compliance with local emissions regulations without straining resources.

- For Large Combustion Plants:

With robust Continuous Emissions Monitoring Systems (CEMS), CODEL provides real-time data and analytics, enabling operators to address issues promptly. These systems are designed to meet stringent environmental standards while optimizing processes for efficiency and reduced emissions.

By choosing CODEL, operators gain access to advanced technologies such as optical analysers, electrochemical sensors, and laser-based systems. These tools offer reliable data to demonstrate compliance, optimize performance, and minimize the environmental footprint of combustion plants.

Our Range of Combustion Plant Monitors Include:

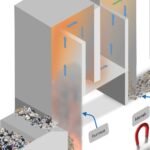

The GCEM40 analyser is an in-situ device which is cost-effective, low maintenance and designed both for process control and emissions monitoring.

CO, NOx, SO2, HCl, CH4, CO2 & H2O

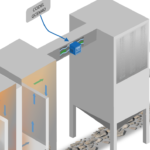

The GCEM40E hot extractive multi-channel gas analyser is CODEL’s industry-proven continuous emissions monitor for difficult applications

CO, NOx, SO2, HCl, CH4, CO2 & H2O

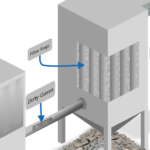

The DCEM2100 is a dual-pass transmissometer configured for the continuous measurement of opacity and dust concentration in flue gases.

CODEL’s unique flow monitors measure the velocity of stack gases using a highly accurate time of flight measurement that is derived from a cross correlation analysis of the infra-red emissions of the turbulent gas.

Gas Flow

Ask a question

For further information on any of our products, please complete our enquiry form and a member of staff will respond as soon as possible.

You can also call: +44(0)1629 814351