Suporte mundial

Over 25 distributors and support centres worldwide

Contratos de manutenção flexíveis

Contratos específicos de fábrica sob medida com suporte 24 horas

30 years experience

Desenvolvendo, fabricando e instalando

Advancing Emission Monitoring: Precision Measurement of Stack Gas Velocity

In the realm of emission monitoring, precision is paramount. Accurately assessing the stack gas velocity not only ensures compliance with environmental regulations but also provides valuable insights into combustion efficiency and pollutant dispersion. At Codel, Our products elevates stack gas velocity measurement to unprecedented levels of accuracy: Highly Accurate Time of Flight Measurement through Cross-Correlation Analysis of Infrared Emissions.

In essence, the technology leverages the inherent turbulence within stack gases, which manifests as fluctuations in infrared emissions. By analysing these fluctuations and applying advanced cross-correlation techniques, we can precisely determine the time it takes for infrared signals to travel between two points within the gas stream. This time of flight measurement directly correlates with the velocity of the stack gases, offering a direct and robust method for velocity assessment.

Traditional methods of stack gas velocity measurement often rely on simplistic techniques that may yield imprecise results, particularly in turbulent gas flows. However, our innovative approach harnesses the power of infrared emissions and cross-correlation analysis to deliver unparalleled accuracy and reliability.

The benefits of this approach

1. Unmatched Accuracy

By directly measuring the velocity of stack gases using infrared emissions, our technology eliminates the need for cumbersome and error-prone secondary calculations. This results in unparalleled accuracy in velocity measurement, even in highly turbulent gas flows.

2. Real-Time Insights

With highly accurate time of flight measurement, operators gain immediate visibility into stack gas velocity, enabling proactive adjustments to combustion processes and pollutant control systems in real-time.

3. Enhanced Efficiency

Precise velocity measurement is not just about regulatory compliance; it’s also about optimizing combustion efficiency and reducing energy consumption. By fine-tuning combustion parameters based on accurate velocity data, facilities can minimize fuel waste and environmental impact.

4. Cost Savings

The reliability and longevity of our technology translate into long-term cost savings for facilities. With accurate velocity measurement, operators can identify and address inefficiencies before they escalate into costly compliance violations or equipment failures.

5. Future-Proof Solution

As environmental regulations evolve and become more stringent, having a robust and accurate method for velocity measurement is essential. Our technology is designed to meet current regulatory requirements while also providing a foundation for future compliance needs.

Conclusion

At Codel, we’re committed to pushing the boundaries of emission monitoring technology, and our Highly Accurate Time of Flight Measurement system is a testament to that commitment. With its ability to derive precise velocity data from the turbulent gas stream, this innovative solution empowers industries to achieve their emissions reduction goals while maximizing operational efficiency.

In conclusion, accurate measurement of stack gas velocity is not just a regulatory necessity; it’s a strategic imperative for industries striving to operate sustainably in an ever-changing landscape. With Codel’s advanced technology, precision, reliability, and efficiency converge to drive environmental stewardship and operational excellence forward.

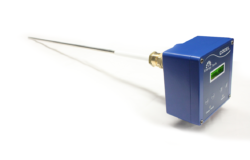

The VCEM 5000/5100 represents the latest generation of CODEL’s unique flow monitors. These systems measure the velocity of stack gases using a highly accurate time of flight measurement that is derived from a cross correlation analysis of the infra-red emissions of the turbulent gas.

The EnergyTech 301 is a low cost dust monitor using well-proven tribo electric technology providing accurate and rapid results. The EnergyTech 301 requires no critical alignment and has no optical surfaces to keep clean.