Biomass Monitoring

What is Biomass Monitoring?

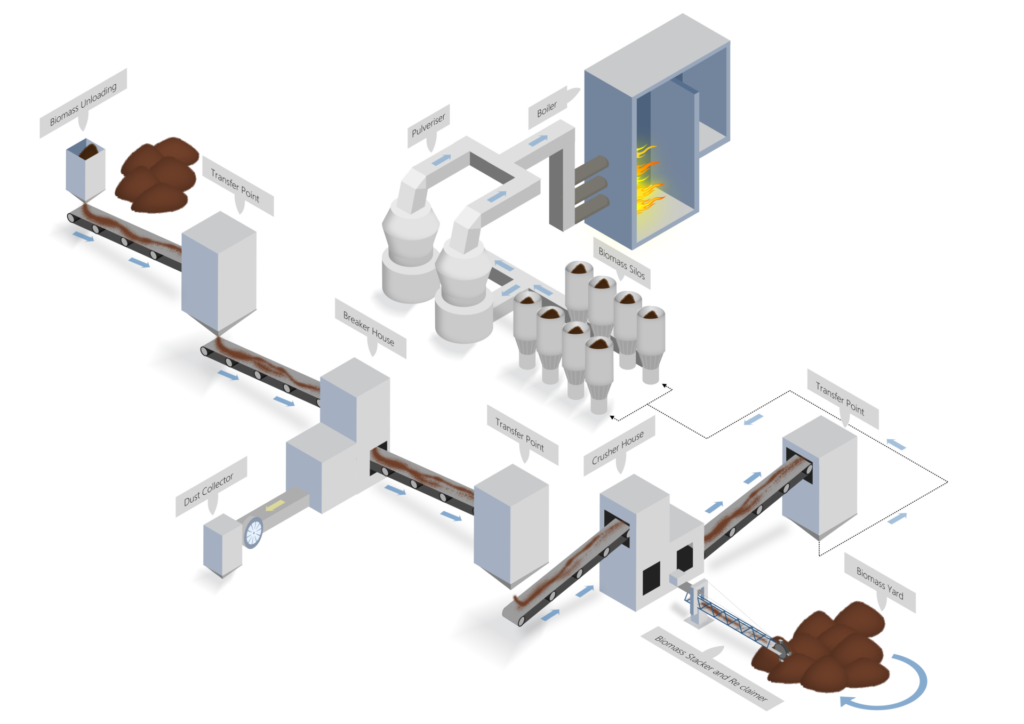

Biomass Monitoring is a critical safety practice used in industries relying on biomass for energy production. Biomass materials, such as wood pellets, agricultural waste, and organic matter, are prone to spontaneous combustion, posing significant risks. Fires often originate in hotspots when biomass absorbs oxygen and generates heat. If undetected, these hotspots can lead to smouldering fires, releasing dangerous levels of carbon monoxide (CO). Continuous measurement of CO levels in biomass mills, silos, and other handling systems provides early detection of fires, even before surface temperatures rise. This proactive monitoring prevents catastrophic damage to equipment and ensures the safety of personnel.

Our Range of Biomass Monitors Include:

- CO

- O2

Why Is It Important to Monitor Biomass?

Monitoring emissions in biomass facilities is essential for maintaining safe, efficient, and environmentally responsible operations. Biomass combustion, like other fuel sources, produces carbon monoxide (CO), which can build up to dangerous levels if not carefully managed. CO build-up often indicates the presence of smouldering fires, posing a severe combustion hazard. Continuous CO monitoring provides early detection, enabling operators to respond quickly, mitigate risks, and protect personnel and equipment.

Beyond safety, emission monitoring supports regulatory compliance and environmental responsibility. Biomass combustion can generate pollutants such as nitrogen oxides (NOx), sulphur dioxide (SO₂), and particulate matter (PM). Effective monitoring ensures emissions remain within permissible limits, minimizing environmental impact and avoiding regulatory fines.

Additionally, emission monitoring enhances operational efficiency. By providing real-time data, monitoring systems help operators optimize combustion processes, reduce downtime, and prevent costly equipment damage. Ensuring safe and sustainable energy production, biomass monitoring supports operational goals while maintaining a commitment to environmental stewardship.

Why Choose CODEL's Products for Biomass Monitoring?

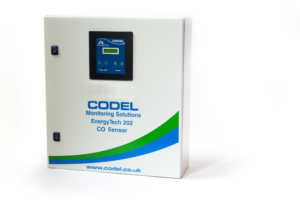

CODEL’s biomass monitoring solutions deliver advanced technology and reliable performance to meet the rigorous demands of biomass energy facilities. With continuous CO monitoring, CODEL’s ET200 Series systems provide real-time data on gas concentrations, ensuring early detection of potential hazards and enabling swift corrective actions.

Equipped with alarm and alert systems, CODEL ET200 Series monitors promptly notify operators of any anomalies, enhancing workplace safety and preventing dangerous incidents. The data logging and reporting capabilities facilitate comprehensive analysis and compliance with regulatory requirements, offering valuable insights into operational efficiency and emissions control.

Designed for easy installation and low maintenance, CODEL’s ET200 Series monitoring systems provide a cost-effective solution for biomass facilities. By choosing CODEL’s products, operators can ensure the highest standards of safety, environmental compliance, and operational excellence in biomass energy production.

Our range of Biomass Monitors:

A detecção precoce de incêndios em fábricas de pulverização de carvão é essencial para evitar danos catastróficos às instalações e evitar a ameaça de ferimentos para o pessoal

CO & O2

Como alternativa ao analisador EC CELL EnergyTech 201, o EnergyTech 202 utiliza uma bancada óptica infravermelha para a medição de CO.

CO

O EnergyTech 203 utiliza a mesma bancada óptica infravermelha do EnegyTech 202, mas inclui uma medição de oxigênio baseada em Zircona.

CO & O2

Faça uma pergunta

Para obter mais informações sobre qualquer um de nossos produtos, preencha nosso formulário e um membro da equipe responderá o mais rápido possível.

Você também pode ligar: +44(0)1629 814351