Поддержка по всему миру

Over 25 distributors and support centres worldwide

Гибкие контракты на техническое обслуживание

Индивидуальные контракты для конкретного завода с круглосуточной поддержкой

30 years experience

Разработка, производство и установка

Enhancing Industrial Safety: The Triboelectric Dust Monitor and Burst Bag Detection

In the realm of industrial operations, maintaining a safe and efficient working environment is paramount. Dust monitoring and Burst Bag Detection are crucial components in industries where airborne particles pose risk. Among the arsenal of tools designed to mitigate these risks, the Triboelectric Dust Monitor stands out as a pivotal instrument. Combined with burst bag protection systems, it offers a comprehensive solution to safeguarding industrial processes. Let’s delve into the significance of these technologies and their applications in ensuring workplace safety and efficiency.

Understanding the Triboelectric Dust Monitor

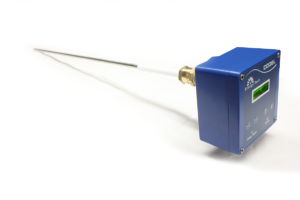

Triboelectric Dust Monitors, like the EnergyTech 301, are a used measure the concentration of airborne particulates in industrial settings. It operates on the principle of triboelectricity, where particles passing through an electric field generate an electric charge. This charge is then measured to determine the concentration and size distribution of dust particles present in the air.

Key Features and Benefits:

Мониторинг в реальном времени:: The monitor provides continuous, real-time data on dust levels, enabling prompt intervention in case of abnormal readings.

High Accuracy: With advanced sensing technology, these monitors offer precise measurements, ensuring reliable data for decision-making.

Remote Monitoring Capabilities: Our EnergyTech 301 Triboelectric Dust Monitors are equipped with remote monitoring capabilities, allowing for monitoring from a centralized control room or even through mobile devices, enhancing accessibility and convenience.

Applications of Burst Bag Protection

Where dust collection systems are employed, the use of fabric filter bags is common for capturing airborne particles. However, these bags are susceptible to bursting or leaking, which can lead to safety hazards and operational inefficiencies. Burst bag protection systems are specifically designed to address these challenges.

How Burst Bag Protection Works:

Burst bag protection systems typically consist of sensors that detect pressure differentials within the dust collection system, when a burst or leak occurs in a bag, the pressure within the system changes, triggering alarms and automated actions to mitigate the issue.

Advantages of Burst Bag Protection Systems:

- Early Warning System: By promptly detecting bag failures, burst bag protection systems provide early warnings, allowing operators to take corrective actions before the situation escalates.

- Prevention of Contamination: Prevents the release of dust into the atmosphere or the surrounding environment, safeguarding air quality and complying with regulatory standards.

- Сокращение времени простоя:: Minimizes downtime by enabling proactive maintenance and preventing costly shutdowns due to equipment failures or safety breaches.

Integration for Enhanced Safety and Efficiency

The synergy between Triboelectric Dust Monitors and burst bag protection systems offers a comprehensive approach to dust monitoring and management in industrial settings. By integrating these technologies, companies can create a robust safety net that not only detects airborne particulates but also responds swiftly to potential hazards, ensuring the well-being of personnel and the integrity of equipment.

Conclusion

In an era where workplace safety and environmental stewardship are paramount concerns, the utilization of advanced technologies like Triboelectric Dust Monitors and burst bag protection systems is indispensable. By investing in these solutions, industries can not only mitigate risks associated with dust exposure but also enhance operational efficiency and regulatory compliance. As we continue to prioritize safety and sustainability in industrial practices, these innovations will play an increasingly vital role in shaping the future of industrial operations.

The DCEM2100 dust monitor provides a continuous measurement of opacity or dust concentration in flue gases by continuously measuring the transmissivity of visible light across a process duct or stack.

The EnergyTech 301 is a low cost dust monitor using well-proven tribo electric technology providing accurate and rapid results. The EnergyTech 301 requires no critical alignment and has no optical surfaces to keep clean.