Worldwide Support

Over 25 distributors and support centres worldwide

Flexible maintenance contracts

Tailor made plant specific contracts with 24Hr Support

30 years experience

Developing, manufacturing and installing

The Requirement for SCR & SNCR

For decades coal has been the fuel of choice for most power stations around the world but also happens to be the most pollutant. The environmental regulation in Europe, China and India has stringent emission limits which coal fired power stations are finding it increasingly difficult and expensive to comply with and are therefore employing such systems as SCR and SNCR.

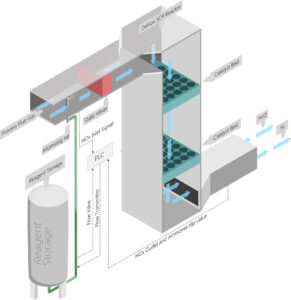

Selective catalytic reduction (SCR) systems are typically found on small and large boilers, gas turbines, diesel engines and even automobiles and have shown to reduce NOx by 70-95%. NOx is one of the primary pollutants generated in a fossil fuel combustion process. Their presence in the atmosphere has a negative impact on the environment (smog, acid, rain, reduced visibility) and human health (respiratory problems) therefore this very same NOx reducing technology is applied to power stations all around the world.

How it works

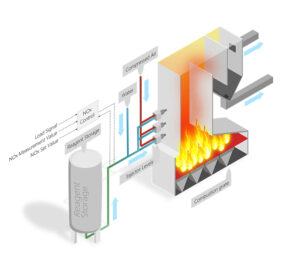

In the combustion process nitrogen reacts with oxygen in high temperature conditions to produce nitrogen oxides (NOx). Total NOx production is the sum of nitrogen monoxide and nitrogen dioxide NO₂. Emission limits for NOx require plants to run DeNOx process in order to reduce the NOx emission below allowable limits.

The Nitrogen oxides concentration in the flue gas, can be effectively reduced by reacting them with ammonia water, or urea in high temperature. Ammonia/urea reacts with both nitrogen monoxide NO and nitrogen dioxide NO₂, to produce nitrogen N₂ and water vapor H₂O and CO₂ when Urea is used.

SCR DeNOx installations are common for large coal fired power stations, SNCR technology can often be found in small to mid-size incineration plants and power stations utilising CFB boilers.

What we do

In order to control both SCR and SNCR systems, these processes require monitoring throughout. CODEL offers a range of products that can monitor both input and output gases, flow and dust emissions reliably and accurately using the very latest technology.

Key Facts

SCR NOx inlet outlet monitoring

– NOx at the inlet is monitored to determine the dose, and control injection of ammonia, fed into the catalyst which in turn reduces the operational costs.

– Outlet NOx is monitored to optimize De-NOx process and assure compliance with environmental regulation.

Recommended CODEL products: GCEM 40E

SCR Flow Control

– Reduced use of reagent by controlling flow and therefore increasing efficiency.

– Monitor catalyst reaction performance.

Recommended CODEL products: VCEM 5100

SNCR NOx

– Control and optimization of denitrification process. Determine and control the dose of ammonia, NH₃ fed into the combustion zone.

Recommended CODEL products: GCEM 40E

To find out more visit:

https://www.codel.co.uk/products/stack-emission-monitoring/gas-analysers/extractive/

https://www.codel.co.uk/products/stack-emission-monitoring/flow-monitors/flue-gas-velocity/

Ask a question

For further information on any of our products, please complete our enquiry form and a member of staff will respond as soon as possible.

You can also call: +44(0)1629 814351